WARREN, Mich.—If you've been following General Motors' development of electric vehicles on its Ultium platform, you'd be forgiven for thinking that it hasn't gone entirely smoothly. While plagued by some initial hiccups, GM has worked through those issues and now has a total of 12 EVs on the road. By my count, that's nine more than Ford, the crosstown rival that had a significant lead in this generation of EVs.

Furthering GM's advancement is the development of new battery technologies. Kurt Kelty, the company's newest head of batteries (after spending 12 years at Tesla), told me that new technology is a way to get to mass adoption of EVs.

"There needs to be price parity between gasoline and electric," he told me. "Without the tax credit."

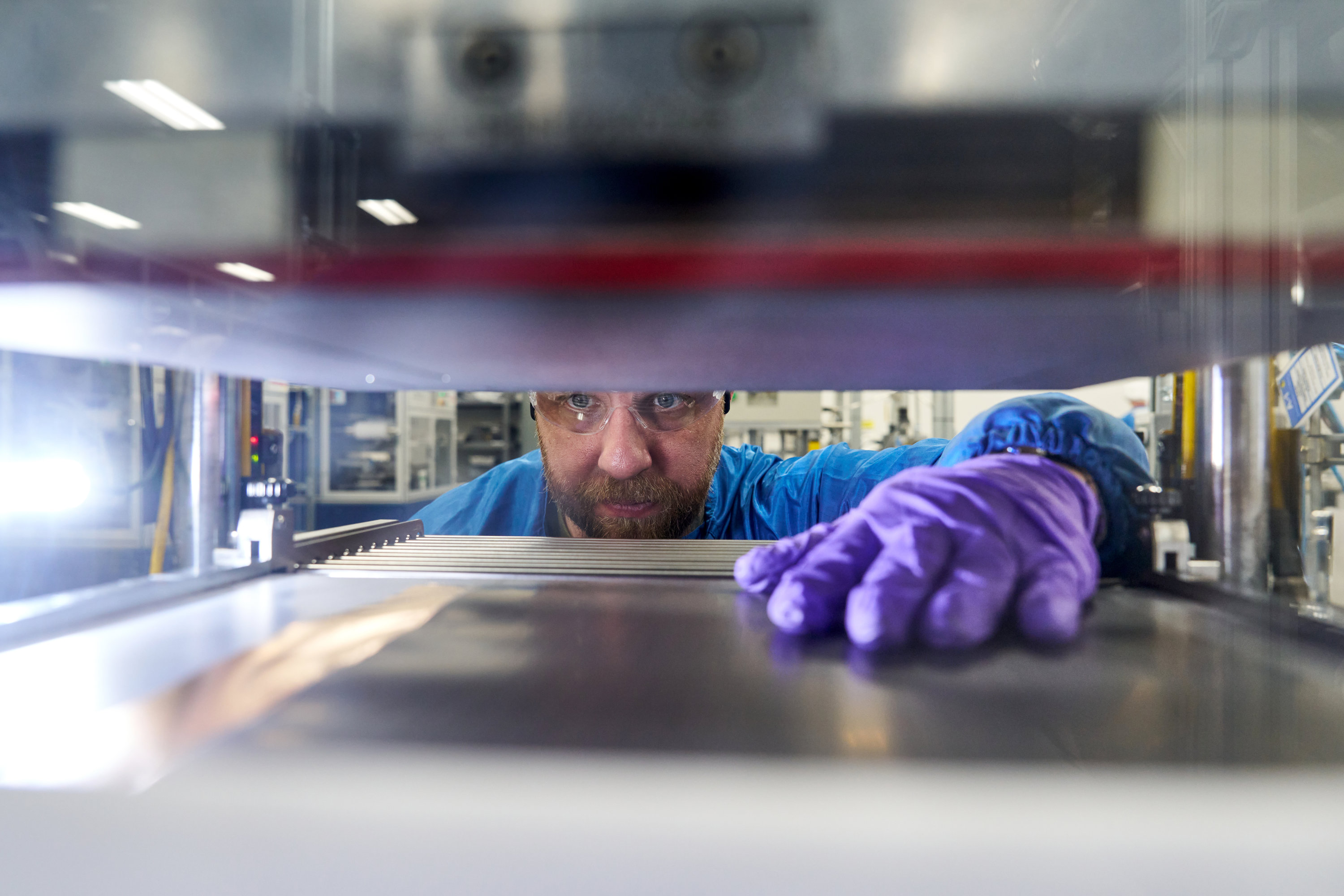

Right now, Kelty says the price differential between the two is around $7,500, which non-coincidentally is the amount of the current federal tax incentive. That's why new—and cheaper—technologies are important and the reason I went to GM's Warren Technical Center, where the company provided a sneak peek at its LMR battery technology.

"Our goal is to reduce cost," Kelty said. The company expects LMR to do just that.

LFP price + NCM range = LMR?

So what is LMR? Lithium manganese-rich is a lithium-ion technology designed to remove a significant amount of cobalt from the cathode, which reduces the cost of the battery to near LFP (lithium iron phosphate) levels, while maintaining more energy density.

"We expect to have near-NMC [nickel manganese cobalt] range for the price of an LFP battery," said Andy Oury from the company's battery team. While the company wouldn't talk about price numbers—the technology is set to appear in trucks in 2028—it said the range will be about 30 percent greater than today's maximum-range LFP packs.

GM will use prismatic cells for its LMR tech, and the packs will reduce in complexity from the setup in its current electric trucks. "We're reducing the number of cells to six, down from 24," Oury said. These new cells will live in the space currently occupied and exist alongside LFP and NMC batteries both in the showroom and on the assembly line.

Loading comments...

Loading comments...